Agricultural Automation Solutions: Advanced Manufacturing for Farming Equipment and Heavy Machinery

Modern agriculture demands durability and efficiency. Industrial Tool, Inc. (ITI) delivers custom machining solutions and robotic automation for machining systems for agriculture, enhancing production of farming equipment and heavy machinery.

With 50 years of machining innovation, ITI offers turnkey engineering systems that ensure precision, scalability, and reliability for ag OEMs and suppliers.

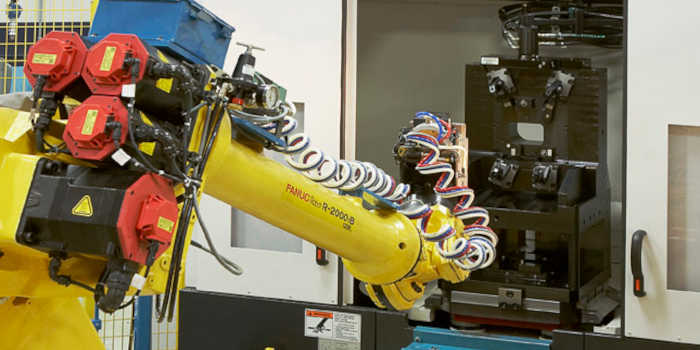

Robotic Assembly Efficiency

ITI’s precision engineering solutions tackle aerospace tolerances with:

- Automated Welding Cells: Precision for tractors and harvesters

- Robotic Machine Tending: Robotic systems for material handling of large parts

- Vision-Guided Robotic Systems: Quality checks for machinery components

These custom robotics solutions for manufacturing boost throughput and cut labor costs.

Custom Workholding for Large Parts

ITI’s custom-engineered manufacturing fixtures ensure accuracy:

- Custom Hydraulic Workholding Fixtures: Secure heavy components

- Specialized Fixturing: Repeatable precision for welded assemblies

- Adaptive Workholding: For complex ag parts

Our dependable workholding solutions for complex machining reduce waste and improve efficiency.

Durable CNC Machining

ITI’s precision engineering solutions deliver:

- Multi-Axis CNC Machining: Frames, gears, and drivetrains

- Chip Management: Longevity in high-speed operations

- Turnkey Machining System Design: CNC programming and process development

Rugged automated manufacturing systems produce wear-resistant parts.

Boost Throughput, Meet Demand

ITI’s solutions keep pace with seasonal needs:

- Faster cycles via automated assembly systems

- Scalable output with application-driven solutions

- Consistent quality for durable equipment

Stay competitive with cycle time optimization for machining.

Minimize Downtime

ITI ensures uptime with:

- Predictive Maintenance: Real-time diagnostics

- Rugged FANUC Systems for 24/7 runs

- Redundant automation for seamless operation

Reliable performance and precision in machining systems cut delays.

Scalable Future-Proofing

ITI adapts to ag evolution with:

- Modular robotic systems integration

- Smart automation for data-driven processes

- Custom tooling Anoka MN for next-gen machinery

Stay ahead with Minnesota manufacturing company expertise.

Elevate Ag Manufacturing

Industrial Tool Inc. enhances efficiency with custom automation systems. Contact ITI to explore turnkey engineering for farming equipment success.

Reduce Labor Costs

Lower Change Over Time

Increase Machine Utilization

Lower Safety Risks

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

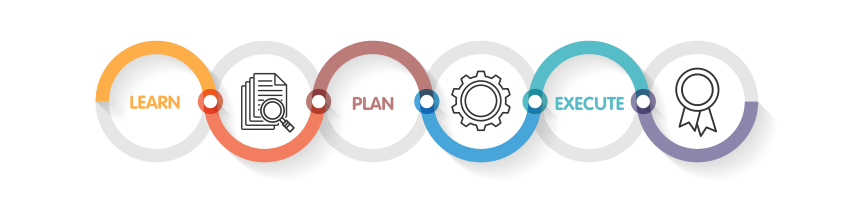

ITI HELPS YOU SUCCEED BY UNDERSTANDING YOUR NEEDS. ONE PARTNER TO CREATE MODERN SOLUTIONS.

- CUSTOMIZED CUTTING TOOLS

- MANUAL/HYDRAULIC FIXTURE REQUIREMENTS

- SPINDLE LOAD MONITORING

- PART PROBING AND VISION SYSTEMS

- HEAVY DUTY INFEED/OUTFEED SOLUTIONS

- CUSTOMIZED CUTTING TOOLS

- MANUAL/HYDRAULIC FIXTURE REQUIREMENTS

- SPINDLE LOAD MONITORING

- PART PROBING AND VISION SYSTEMS

- HEAVY DUTY INFEED/OUTFEED SOLUTIONS

THE ITI WAY.

ITI EXCLUSIVE CHECKLIST FOR ACHIEVING SUCCESS IN THE AGRICULTURAL INDUSTRY.