MITI Maxx: High-Performance CNC Machining Solutions

Engineered by Industrial Tool, Inc. (ITI), a Minnesota manufacturing company with 50 years of machining innovation, the MITI Maxx series delivers durability, precision, and efficiency for flexible, fast deployable CNC automation operations. Built for extended tool life and minimal downtime, it excels in machining steel, aluminum, titanium, and composites—perfect for high-volume production and custom precision needs.

With custom-engineered manufacturing fixtures and turnkey machining system design, MITI Maxx cuts maintenance costs and optimizes cycle times for cost-effective performance.

Precision at High Speeds

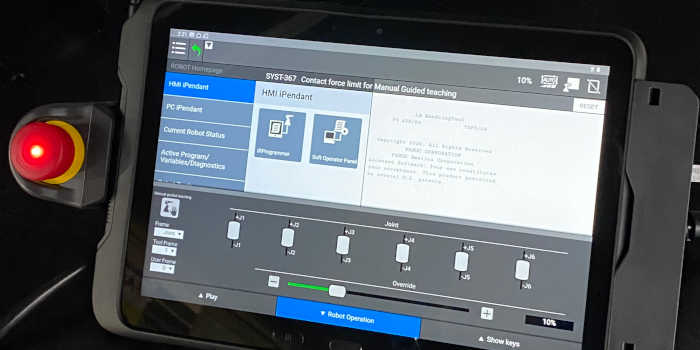

MITI Maxx meets the demands of micron-level accuracy with fast cycle times and multi-axis precision. Featuring FANUC robotic automation solutions for machining, it ensures consistent results across aerospace, medical, and defense applications. Precision robotic tending for CNC machines and AI-driven robotic inspection for machining reduce errors and uphold strict quality standards.

From automotive components to aerospace fixtures, MITI Maxx delivers tailored, high-speed accuracy.

Versatile for Any Scale

Whether it’s high-volume runs or one-off parts, MITI Maxx adapts seamlessly. Quick-change CNC fixtures and modular setups provide flexibility for job shops, OEMs, and aerospace suppliers. Vision-guided robotic systems and automated traceability solutions streamline inspection and compliance, ensuring precision and repeatability.

This scalability keeps production flowing, no matter the task.

Lower Costs, Higher Efficiency

MITI Maxx boosts profitability with IoT-enabled automation and predictive maintenance, cutting energy use and waste while maximizing uptime. Automated CNC programming and smart manufacturing strategies drive throughput, while hydraulic clamping systems and chip management in machining fixtures minimize inefficiencies.

It’s lean, sustainable, and built for results.

Built for Every Industry

MITI Maxx serves aerospace, medical, automotive, agriculture, and defense with unmatched adaptability. It handles ITAR-compliant automation solutions, precision workholding fixtures, and medical-grade components—machining hardened alloys, composites, and aerospace materials with ease.

Robotic assembly solutions and laser marking for manufacturing ensure compliance and traceability across the board.

Expert Support Included

ITI backs MITI Maxx with comprehensive service:

- On-site setup and calibration.

- Cycle time optimization.

- Remote diagnostics and maintenance.

- Precision end-of-arm tooling integration.

Our support ensures peak performance and precision in machining systems for lasting success.

Why MITI Maxx?

- 50 years of ITI expertise since 1974.

- Integrated Maruka USA tools and FANUC Integrator skills.

- Ongoing support for dependable workholding solutions for complex machining.

MITI Maxx delivers ROI with application-driven solutions that eliminate bottlenecks.

Elevate Your Operations

For high-speed precision and cost-effective automation, MITI Maxx is the ultimate CNC solution. Contact ITI today to see how our custom robotics solutions for manufacturing can transform your production.

A Practical Look for Industry Leaders Like You

Hey there, manufacturing pros! If you’re feeling the pressure to boost output, cut costs, or keep your team safe, you’re not alone. That’s where collaborative robots—cobots—come in. These aren’t the clunky, caged robots of the past. Cobots are built to work with your team, not replace them, making your shop floor more efficient and a whole lot easier to manage.

The buzz around cobots is real—according to the International Federation of Robotics (IFR), 84% of businesses plan to bring robotics, including cobots, into their operations over the next ten years (IFR 2023). Why? Because they tackle the stuff keeping you up at night:

- More output: Cobots take on the repetitive grunt work so your team can focus on the big-picture stuff (Automate.org).

- Safer days: With sensors and safety features, they’re like a trusted coworker who never swings a wrench too hard (Automate.org).

- Lower costs: They’re quick to set up and won’t break the bank—perfect if you’re not running a mega-factory (Universal Robots Case Study, 2022).

In this guide, we’ll walk you through what cobots can do for your operation, share some real success stories, and give you a no-nonsense plan to get started. Ready to see how they’re shaking up manufacturing? Let’s dive in.

What Exactly Are Cobots? Your New Shop Floor Sidekick

Picture this: a robot that doesn’t need a fancy cage or a PhD to run it. That’s a cobot. These machines are designed to team up with your workers in the same space, no barriers required. Here’s what makes them special:

- Safety first: They’ve got joints that stop if they bump into someone and sensors that know when a person’s close (Automate.org).

- Easy to use: You can often “teach” them by moving their arms or using a simple app—no coding required (Universal Robots Case Study, 2022).

- Team players: They’re here to help, not take over (IFR 2023).

How do they stack up to old-school robots? Traditional industrial robots are powerhouses for high-volume jobs, but they’re expensive, tricky to program, and need safety zones. Cobots? They’re affordable, flexible, and ready to jump into smaller runs or varied tasks alongside your crew.

For a deeper dive into how cobots fit into modern Industry 4.0 trends, check out our guide on smart manufacturing automation.

Where Cobots Are Making a Difference

Real Stories from the Shop Floor

Cobots are popping up everywhere, from car plants to medical labs. Here’s how they’re helping folks like you:

- Automotive Manufacturing

- What they do: Assembly, welding, painting—you name it.

- Real win: BMW added cobots to their line and saw tighter precision and fewer mistakes, according to a 2022 report by Automate.org. Ford is using them for paint jobs and final checks, catching flaws before cars roll out (Automate.org).

- Aerospace

- What they do: Drilling, riveting, handling parts with care.

- Real win: Lockheed Martin brought in cobots for F-35 assembly, improving production efficiency and reducing worker strain (Automate.org).

- Medical & Pharma

- What they do: Packing pills, assembling devices, lab support.

- Real win: Sanofi integrated cobots into their packaging operations, reducing manual labor and improving efficiency (Universal Robots Case Study, 2022).

- Electronics

- What they do: Testing screens, soldering tiny parts.

- Real win: KOYO Electronics tested touchscreens with a cobot, boosting output by 31% and achieving ROI within a year (Universal Robots Case Study, 2022).

For additional success stories on cobot integration, see our article on cobot case studies.

The Bottom Line: A Better Way to Work

Cobots aren’t just tech—they’re a game-changer for shops like yours. They cut costs, boost output, and keep your team happy, all while letting your human expertise shine where it counts.

With AI and new tricks coming, cobots are only getting better. Jump in now, and you’ll be ahead of the curve, ready for whatever’s next.

Thinking about cobots for your line? Reach out to ITI—we’ve got the tools and know-how to get you started. Let’s make your shop smarter, together!

Check out our ultimate cobot Miti Maxx, let’s find the best fit for your needs!

Reduce Labor Costs

Increase Production

Lower Safety Risks

Improve Quality

ITI HAS DEVELOPED THE MOST ROBUST AND AFFORDABLE COBOT SOLUTION IN THE MARKET TODAY.

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

THE ITI WAY.

ITI DEVELOPED A ROBUST AND AFFORDABLE COBOT SOLUTION TO HELP YOU INCREASE PRODUCTIVITY AND BECOME MORE PROFITABLE.

ITI...ALWAYS WORKING.

ITI's EXCLUSIVE COBOT SOLUTION FOR A WIDE VARIETY OF APPLICATIONS.