Advanced Robotic Tending for Engine, Transmission, and Chassis Components

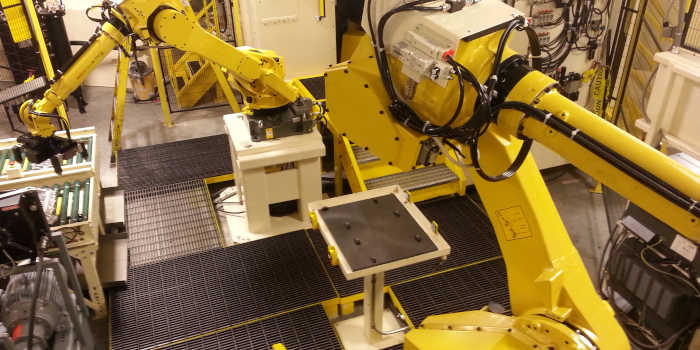

As an Authorized FANUC Systems Integrator, Industrial Tool Inc. (ITI) delivers custom robotics solutions for manufacturing, specializing in robotic automation solutions for machining engine blocks, transmission casings, and chassis components. Our turnkey engineering systems optimize:

- Seamless CNC machine tending with vision-guided robotic systems

- Robotic systems for material handling and precise inspection

- Automated robotic systems for assembly

- Cycle time optimization for machining to boost throughput and cut bottlenecks

By integrating robotics into production lines, ITI reduces labor dependency, enhances workplace safety, and drives performance and precision in machining systems for automotive manufacturing solutions.

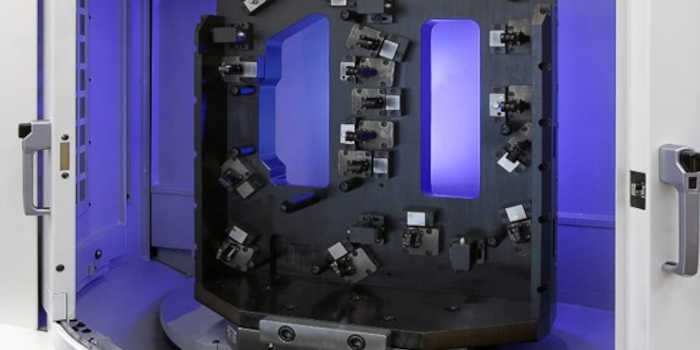

Precision Workholding Fixtures for CNC Machining and Automation

For high-speed machining, custom-engineered manufacturing fixtures from ITI ensure repeatability and stability. Our custom hydraulic workholding fixtures and dependable workholding solutions for complex machining elevate CNC programming and process development. Offerings include:

- Hydraulic clamping systems for fast production

- Workholding fixtures and tombstone fixtures for multi-axis CNC

- Precision end-of-arm tooling for complex applications

Paired with custom automation systems, ITI’s solutions improve part quality, increase throughput, and lower scrap rates—ideal for manufacturing company clients.

Cut Costs, Cycle Times, and Labor Dependency

ITI’s turnkey machining system design and automated manufacturing systems deliver cost savings in high-volume production. Our application-driven solutions focus on:

- Minimizing manual labor with automated assembly systems

- Shortening cycles via cycle time optimization for machining

- Maximizing uptime with machine tool integration experts

From Minnesota machining company roots, ITI boosts profitability and ROI with vertical integration of machining services.

Boost Quality, Consistency, and Repeatability

ITI’s vision systems for manufacturing and advanced inspection systems ensure defect-free output with tight tolerances. Key features:

- Vision systems for quality inspection in automotive manufacturing

- Automated part marking solutions and laser marking for manufacturing

- OEM equipment integration for seamless assurance

Our precision engineering solutions guarantee consistent, high-performance components—perfect for medical device machining solutions or die-cast manufacturing systems.

Comprehensive Support and Optimization

Founded in 1974 as machining experts, ITI offers more than installation. Our 50 years of machining innovation shine through:

- Proactive maintenance and automated CNC programming for efficient machining

- Technical support for robotic systems integration

- Operator training for turnkey engineering efficiency

With a legacy tied to ITI automotive industry tooling origins we keep your operations cutting-edge.

Future-Proof Your Manufacturing with ITI

Whether it’s automation in heavy equipment manufacturing, workholding fixtures, or machining systems for automation, Industrial Tool Inc. provides custom machining solutions that drive productivity and cost efficiency. From custom tooling Anoka MN to North American manufacturing solutions, we’ve got you covered.

Contact ITI today to explore how to integrate robotic automation into machining and elevate your capabilities with FANUC Systems expertise.

Reduce Cycle Times

Lower Labor Costs

Increase Machine Utilization

Mitigate Down Time

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

ITI HAS ENGINEERED AUTOMOTIVE SOLUTIONS FOR 50 YEARS. OUR PRODUCT IS MAKING YOU SUCCESSFUL.

- TIME STUDIES

- FIRST ARTICLE PARTS

- PPAP REQUIREMENTS

- CHIP CONTROL

- PART SEAT CONFIRMATION

- INSPECTION REQUIREMENTS

- TIME STUDIES

- FIRST ARTICLE PARTS

- PPAP REQUIREMENTS

- CHIP CONTROL

- PART SEAT CONFIRMATION

- INSPECTION REQUIREMENTS

THE ITI WAY.

ITI EXCLUSIVE CHECKLIST FOR MAKING YOU MORE COMPETITIVE IN THE AUTOMOTIVE INDUSTRY.