Custom Machines and CNC Machining Centers: Precision and Automation

Industrial Tool, Inc. (ITI), a Minnesota manufacturing company with 50 years of machining innovation, designs custom machining solutions and turnkey engineering systems for global manufacturers. Our high-precision CNC machining centers serve aerospace, automotive, medical, and defense with scalable, future-ready performance.

Standalone or Integrated Systems

ITI’s custom automation systems fit any setup:

- Standalone Machines: Specialized units for accuracy and flexibility, and high-volume machining and grinding.

- Integrated Lines: Full solutions with CNC, robotics, and vision systems for seamless efficiency.

Our turnkey machining system design optimizes production across the board.

Precision for Complex Parts

ITI meets tight tolerances with:

- Multi-axis machining for intricate geometries.

- Custom hydraulic workholding fixtures for consistency.

- Advanced CNC programming for micron-level precision.

As a FANUC Integrator, we deliver ITAR-compliant automation solutions that uphold the highest standards.

Scalable and Future-Ready

Our machines grow with you:

- Modular designs for easy upgrades.

- Retrofitting with IoT-enabled automation.

- Smart manufacturing for real-time tracking.

ITI’s application-driven solutions cut downtime and keep you competitive.

Tailored for Performance

We engineer bespoke solutions:

- Custom machine tools for unique parts.

- Precision workholding fixtures for high-volume runs.

- Cycle time optimization for maximum output.

ITI’s precision engineering solutions tackle specialized challenges with efficiency.

Seamless Automation Integration

As a FANUC Integrator, ITI blends robotics and smart controls:

- Robotic tending for unattended machining.

- Automated tool and part handling.

- AI-driven robotic inspection for machining quality.

Our custom robotics solutions for manufacturing reduce errors and scale effortlessly.

Reliable High-Throughput

For mass production, ITI offers:

- High-output lines for automotive and aerospace.

- Heavy-duty designs for 24/7 uptime.

- Cooling and chip management for nonstop runs.

These dependable workholding solutions for complex machining save time and costs.

Why ITI?

- 50 years of expertise since 1974.

- Integrated Maruka USA tools and FANUC skills.

- Ongoing support for performance and precision in machining systems.

ITI ensures ROI with solutions that eliminate bottlenecks.

Elevate Your Production

Partner with ITI for custom machining centers and robotic automation solutions for machining. Contact us today to explore how our turnkey systems can transform your operations.

Reduce Machine Foot Print

Increase Productivity

Lower Labor Costs

Optimize Machine Utilization

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

THE ITI WAY.

ITI UNDERSTANDS THE DEMANDS OF HIGH VOLUME PRODUCTION. FOR 50 YEARS, ITI HAS BEEN THE MOST TRUSTED NAME IN THE CUSTOM MACHINE INDUSTRY.

ITI...ALWAYS WORKING.

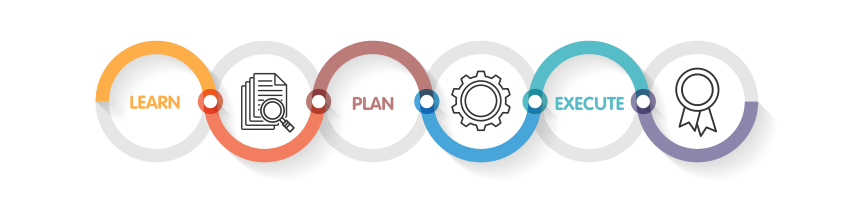

ITI EXCLUSIVE CHECKLIST FOR PLANNING A SUCCESSFUL CUSTOM MACHINE PROJECT.