Robotic Automation Systems: Precision and Efficiency in Manufacturing

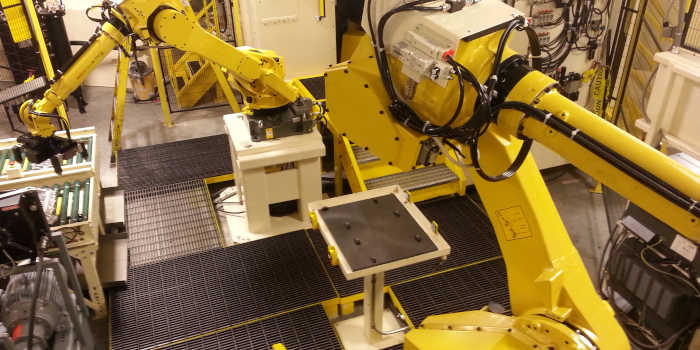

Industrial Tool, Inc. (ITI), a Minnesota manufacturing company, delivers custom robotics solutions for manufacturing that enhance efficiency, precision, and safety. As a Certified FANUC Integrator with over 30 years of expertise, we engineer turnkey machining system design for CNC, assembly, and quality control, tailored to high- and low-volume production

Advanced Automation Solutions

ITI’s robotic systems optimize workflows:

- Machine Tending: Precision robotic tending for CNC machines boosts speed, efficiency, quality, and reduces fatigue.

- Part Transfer: Seamless material handling for automotive, aerospace, defense, agricultural, and medical lines.

- Inspection: Vision-guided robotic systems ensure defect-free precision with high speed.

- Assembly: Automated solutions streamline multi-step processes for OEMs.

- Palletizing / de-palletizing and boxing for packaging equipment.

These custom automation systems cut cycle times and improve consistency.

Tailored for Any Scale

ITI’s robotic automation adapts to:

- High-volume production with automated fixturing.

- Low-volume, high-mix precision machining with modular setups

Flexible precision end-of-arm tooling ensures quick adjustments without downtime.

Industry-Specific Expertise

We serve:

- Automotive: High-speed production automation.

- Aerospace & Defense: ITAR-compliant precision solutions.

- Medical: Tight-tolerance machining systems.

- Agriculture & Industrial: Robust material handling.

Our application-driven solutions meet strict standards.

Seamless Integration

ITI’s robotic systems blend with CNC machines, custom hydraulic workholding fixtures, and inspection tools. With FANUC robotic integration and IoT-enabled automation, we deliver:

- AI-driven robotic inspection for machining.

- Real-time monitoring for process optimization.

Our machine tool integration ensures reliability across complex lines.

Boosting Safety and Output

- Safety: Automation cuts risks and meets OSHA standards.

- Productivity: 24/7 operation with advanced CNC programming.

- Traceability: Smart automation tracks quality in real time.

ITI’s solutions maximize throughput and compliance.

Why ITI?

- 50 years of machining innovation since 1974.

- Integrated OEM CNC machine tools and FANUC expertise

- Ongoing support for performance and precision in machining systems.

We ensure ROI with dependable workholding solutions for complex machining.

Optimize with ITI

Ready to enhance your production? Contact ITI today to see how our custom robotic automation solutions for machining can transform your operations across the Midwest and beyond.

Reduce Labor Costs

Increase Production

Lower Safety Risks

Improve Quality

ROI Calculator

Select your automation budget: $0

How many hours per week is it available? 30

What do you charge for hourly machine rate (in USD)? $50

How much are your operator wages including benefits (in USD)? $15

Return on Investment calculations shown above are approximate. Please reach out to your local sales representative, or click here, if you would like further information.

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

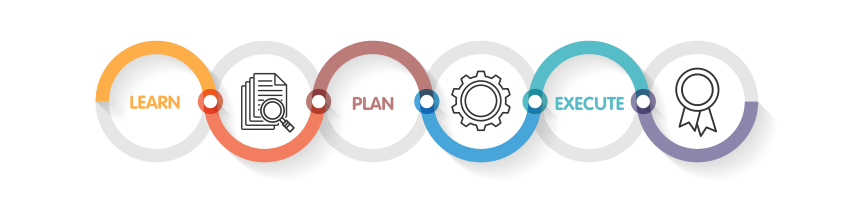

THE ITI WAY.

ITI CONTINUES TO BE COMMITTED TO PROVIDING THE MOST VALUABLE AND ROBUST ROBOTIC AUTOMATION SOLUTIONS IN THE INDUSTRY TODAY. OUR DEDICATED STAFF OF DIRECT EMPLOYEES IS ALWAYS WORKING TO MAKE YOU MORE SUCCESSFUL.

ITI...ALWAYS WORKING.

ITI EXCLUSIVE CHECKLIST FOR PLANNING A SUCCESSFUL ROBOTIC AUTOMATION PROJECT.