Workholding Fixtures: Precision Clamping for CNC & Automatio

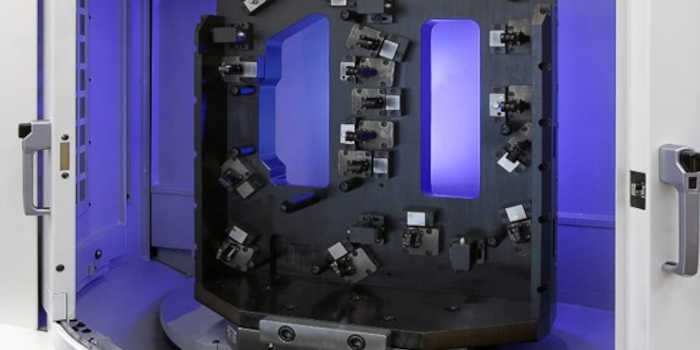

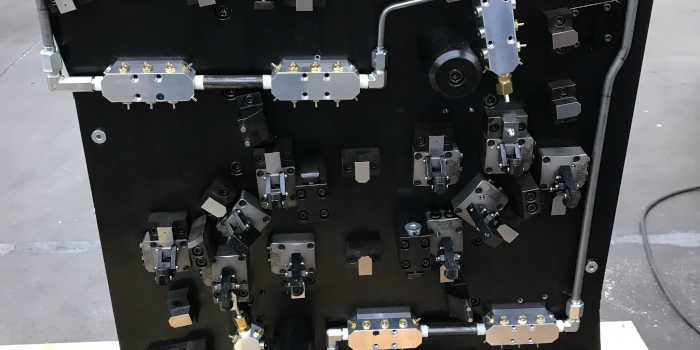

Industrial Tool, Inc. (ITI), a Minnesota manufacturing company, designs custom-engineered workholding fixtures that enhance CNC machining, robotic systems integration, and high-volume production. Our hydraulic and pneumatic clamping solutions deliver stability, accuracy, and repeatability for efficient, error-free operations.

With turnkey machining system design, ITI ensures seamless integration into your production line—reducing setup times and boosting quality across aerospace, automotive, medical, and more.

High-Performance Clamping Systems

ITI’s custom automation systems include:

- Hydraulic Workholding Fixtures: High-force clamping for precision in aerospace, automotive, and defense.

- Pneumatic Workholding Fixtures: Lightweight, fast setups for robotic automation and cycle time optimization.

- Custom Fixtures: Modular designs paired with FANUC robotic inspection systems for CNC lines.

- Truly single-sourced, all workholding fixtures are designed and fully manufactured in-house.

Built to meet strict standards, these solutions ensure durability and performance.

Engineered for Precision and Stability

Our precision engineering solutions prioritize accuracy and consistency:

- Compatible with multi-axis CNC machines and robotic assembly solutions.

- Rigid designs for vibration-free, repeatable high-volume production.

- Quick-change CNC fixtures to minimize handling and speed up cycles.

ITI’s workholding eliminates movement, enhancing quality control and machining precision.

Optimized for Speed and Automation ready

ITI’s custom robotics solutions for manufacturing boost production:

- Seamless machine tool integration with FANUC robotic tending systems.

- Automated workholding with AI-driven robotic part transfer.

- IoT-enabled automation for real-time precision monitoring.

These application-driven solutions improve throughput and traceability for OEM integration.

Faster Setups, Higher Efficiency

Efficiency drives our designs:

- Quick-change modular fixtures cut downtime.

- Automated positioning ensures rapid, error-free machining.

- Smart automation lifts throughput while lowering costs.

Paired with advanced CNC programming, ITI’s fixtures optimize operations.

Unmatched Quality Control

ITI ensures tight tolerances and consistency with:

- Hydraulic clamping systems for better tool life and finishes.

- Vision-guided robotic systems for reliable quality checks.

- Automated traceability solutions for defect-free production.

Our dependable workholding solutions for complex machining deliver precision every time.

Tailored for Your Industry

With 50 years of machining innovation, ITI serves:

- Aerospace: Precision fixtures for tight tolerance, ITAR-compliant machining.

- Automotive: High-speed clamps for all die cast and forged parts.

- Medical: Ultra-precise solutions for devices and instruments.

- Defense: Highly customized fixtures, heavy-duty or fragile machining or inspection

Our custom hydraulic workholding fixtures meet diverse demands.

Why ITI?

- 50 years of expertise since 1974.

- Integrated OEM CNC Machine Tools and FANUC Integrator skills.

- Ongoing support for performance and precision in machining systems.

ITI maximizes ROI with solutions that eliminate bottlenecks.

Unlock Efficiency with ITI

ITI’s workholding fixtures enhance accuracy, cut cycle times, and integrate smart automation for data-driven results. Contact us today for a custom quote and see how our precision clamping solutions can transform your production.

Increase Productivity

Reduce Scrap

Optimize Machine Utilization

Improve Quality

0

YEARS IN BUSINESS

0

DIRECT EMPLOYEES

0

YEARS OF EXPERIENCE

0

LOCATION

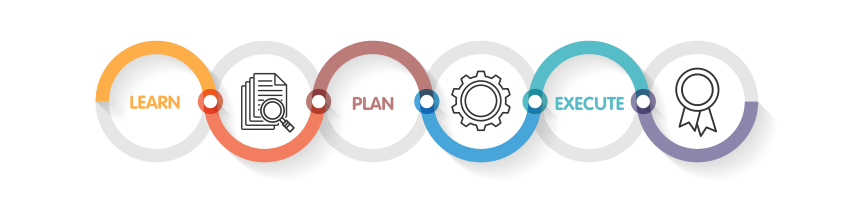

THE ITI WAY.

ITI HAS 5 DECADES OF WORKHOLDING FIXTURE EXPERIENCE. WE ARE DEDICATED TO PROVIDING THE MOST ROBUST AND RELIABLE WORKHOLDING SOLUTIONS FOR YOUR BUSINESS.

ITI...ALWAYS WORKING.

ITI EXCLUSIVE CHECKLIST FOR PLANNING A SUCCESSFUL WORKHOLDING FIXTURE PROJECT.